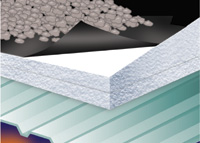

Adding a thermal barrier adds time and materials which increases cost. STYRO-STOP expanded polystyrene (EPS) roof insulation can be applied directly over steel roof decks without a thermal barrier.

Enjoy the benefits of permanent high R-values, superior dimensional stability, and resistance to moisture absorption and physical degradation at a substantial cost savings over other rigid insulation products.

Available in flat, tapered or compound tapered panels ranging from 1.00 – 2.00 pcf, STYRO-STOP is compatible with all major roofing materials and assemblies. It has also been thoroughly evaluated for fire safety performance. STYRO-STOP provides building owners, architectural specifiers and contractors the confidence that comes from its recognition by the nation’s most respected code authorities.

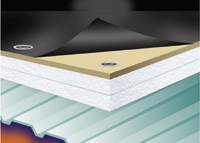

STYRO-STOP has undergone thorough evaluation by ICC-ES and UL for fire safety performance and can be installed directly over steel roof decks.

UL Evaluation Report ER13418 and UL Roof Deck Construction No. 458 recognize STYRO-STOP up to 10” being installed directly over steel roof decks along with a Class A, B or C roof covering of 80 mils or less in ballasted, mechanically fastened and fully-adhered roof assemblies.

Steel Deck: Minimum 22 gauge, 1/2” deep, non-perforated, and maximum 6” flutes.

EPS Thickness: Refer to UL ER13418 or UL Roof Deck Construction No. 458 for various thickness and Types.

Accepted Membranes: Approved EPDM or thermoplastic single-ply that are ballasted, mechanically fastened and fully-adhered.

Cover Board (when required): Refer to UL Roof Deck Construction No. 458 for various cover board options.

For complete assembly information, refer to UL Roof Deck Construction No. 458 or UL Evaluation Report ER13418.

{module_literature filter="item" itemId="195222"}

{module_literature filter="item" itemId="195181"}

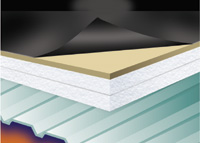

7220 - Roof Deck Insulation: STYRO-STOP is available in tapered and flat panels and in a variety of slopes. Ideal for use in ballasted, mechanically fastened and fully-adhered roof assemblies.

STYRO-STOP is available in a range of sizes to meet your specific application:

Thickness: Maximum insulation thickness varies per assembly and material density.

Width: 24 inches – 48 inches

Length: 48 inches – 96 inches

STYRO-STOP does not contain ozone-depleting CFCs or HCFCs.

Styro-Flex Design Considerations

Styro-Flex Physical Properties ASTM C578

8800 Wyoming Avenue North

Brooklyn Park, MN 55445

Local: (763) 425-4001

Toll Free: (800) 451-6963

Fax: (763) 425-8994

Email: info@styrotech.com